Delay Recording System

Delay Recording System

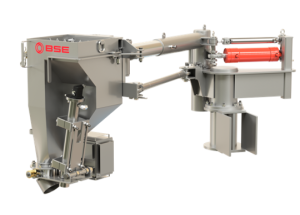

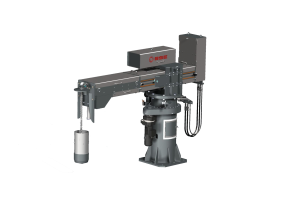

The BSE Delay Recording System (DRS) is a process analysis tool for steel plants that don’t have a Level 2 automation system yet.

It is operated by the operator at the furnace and helps in the fight against delay times, thus providing a huge potential for productivity increase.

FUNCTIONS

- Definition of standard setup times and delay code system reflecting the time balance of the process

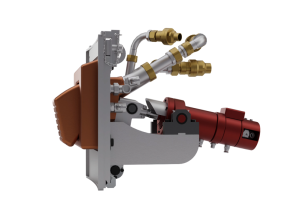

- Accurate time measurement based on automatic process signals

- At each power-off the DRS requests the operator to enter a specific delay code

- The code system with finite number of codes allows classification and precise documentation of main setup and delay times (and causes)

- Automatic generation of statistics and reports

- Process optimization based on standardised reporting

ADVANTAGES

- Process optimization based on standardised reporting

- Reduction of delays provides a huge potential for productivity increase

- Allocation of (and creation of awareness for) small but frequent delays

- Increase of transparency and consistency

- Easiest possible handling enables the operator to focus on the process

- Multi language support

EXPERIENCES

- Operating since 2000 at BSW – Germany

- World-wide satisfied customers using such system