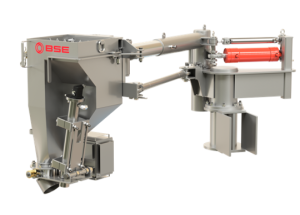

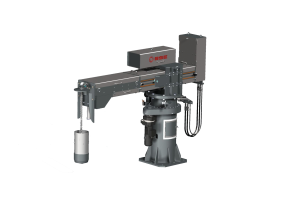

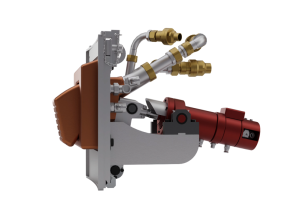

Fume Extraction System

Fume Extraction System

Optimal for our environment and your efficiency!

BSE is a renowned specialist for the layout of clean and efficient melt shops, various analyzis tools and engineering for emission control as well as hardware key components

SOLUTIONS

- Analysis-Conceptual Engineering

- State-of-the-art design for DEC / SEC systems

- FDM (Fluid Dynamic Modelling) Implementation

- EDC (Efficient Dedusting Control)

- HTQ (High Temperature Quenching)

- CFD (Computational Fluid Dynamics)

ADVANTAGES

- Minimized operating cost by process optimization

- Optimum exhaust at the EAF, doghouse, ladle furnace, alloy feeding system as well as melting and casting bay

- Minimized emissions at the stack and from the building

- Minimized investment cost by preservation, reuse and / or upgrade of existing installations parts

- Minimized required down time by possibility of installation during production time

EXPERIENCES

- BSW is the leading benchmark in Europe, in regards to low emission figures

- More than 220 projects executed world-wide