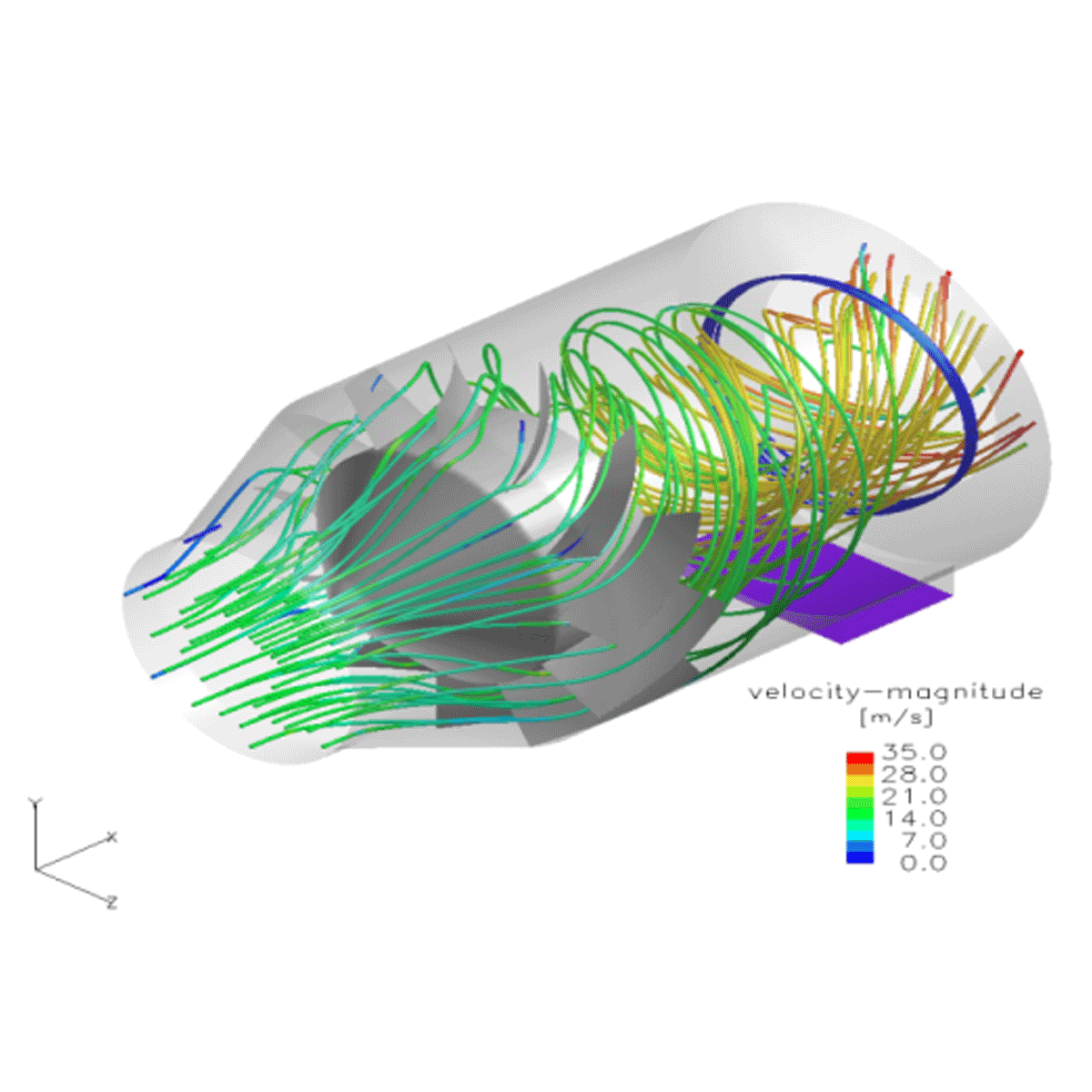

Computational Fluid Dynamic Model

Computational Fluid Dynamic Model

BSE provides Computational Fluid Dynamic investigations to look into details of critical items and applications.

FUNCTIONS

- Simulation of entire ductwork or single parts

- Temperature, velocity and flow parameters

- Providing solutions for optimal off-gas treatment

HTQ - CFD Simulation

ADVANTAGES

The Computational Fluid Dynamic ensures a smooth engineering process and highest performance of the designed dedusting systems for special areas / equipment.

EXPERIENCES

For each High Temperature Quenching (HTQ), BSE performs a CFD analysis